2022-9-26 16:14:25

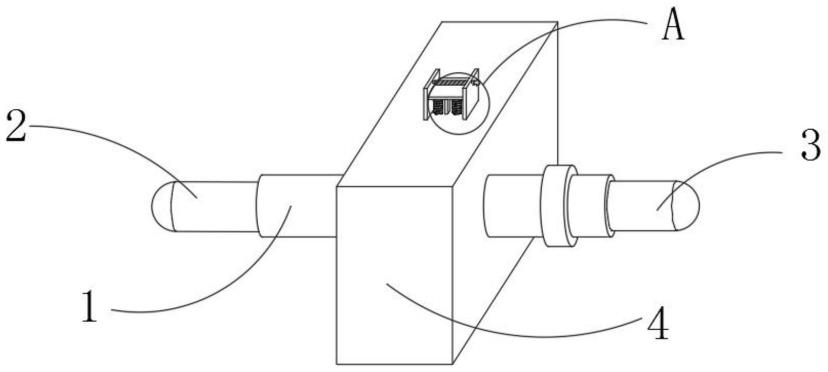

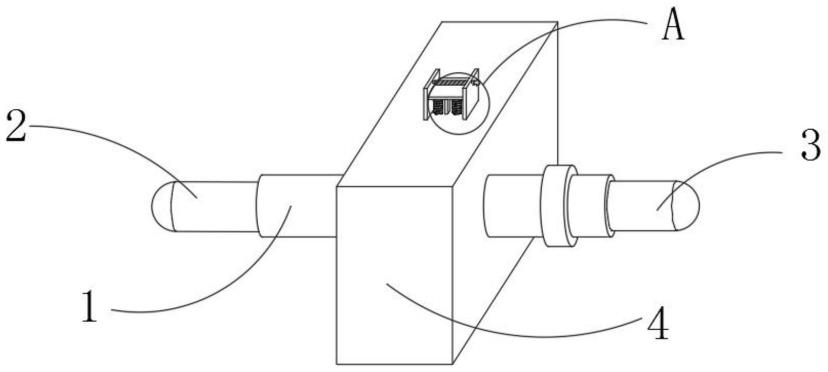

Double end waterproof Pogo pin design

Technical Features:

1. Double-headed waterproof Pogo PIN, including

Pogo pin shell (1), is characterized by: One side wall of the Pogo pin shell (1) is provided with a long needle tube (5), the long needle tube (5) sliding connected with a long needle shaft (2), the long needle shaft (2) extending one end of the long needle tube (5) and sliding connected with the Pogo pin shell (1) inner wall is fixed connected with a riveting block (9), The long needle (5) is provided with a long spring (10), the long spring (10) at both ends of the long needle shaft (2) and the side wall of the insert riveting block (9) is connected, the other side wall of the Pogo pin shell (1) is provided with a short needle (6), the short needle (6) sliding connected with a short needle shaft (3), One end of the short needle shaft (3) extends a short needle tube (6) and is connected with its sliding, the short needle tube (6) is provided with a short spring (7), the two ends of the short spring (7) are respectively connected with the riveting block (9) side wall and the short needle shaft (3) side wall, The outer surface of the Pogo PIN shell (1) is fixedly connected with a mounting plate (4) through a clamping mechanism. 2. According to the double-head waterproof Pogo PIN mentioned in Claim 1, the clamping mechanism comprises a mounting plate (4), a through slot (8), a mounting slot (17), a top block (15), a compression spring (16) and a clamping block (18), and the side wall of the mounting plate (4) is provided with a matching setting slot with the Pogo pin shell (1). The upper surface of the mounting plate (4) is provided with a through groove (8), the Pogo pin shell (1) is extended into the mounting plate (4) and the inner part of the side wall is provided with a mounting groove (17), the sliding groove (17) is connected with a clamping block (18), the clamping block (18) is extended into the through groove (8) and is connected with its sliding, the inner wall of the mounting groove (17) is provided with a compression spring (16), The two ends of the compression spring (16) are respectively connected with the side wall of the clamping block (18) and the mounting groove (17), and the inner wall of the sliding groove (8) is connected with the top block (15), and one end of the top block (15) extends through the groove (8). 3. The double-headed waterproof Pogo PIN mentioned in claim 2 is characterized in that one end of the top block (15) extending through slot (8) is fixably connected with a pressing plate (12). 4. According to the double-head waterproof Pogo PIN mentioned in claim 3, its characteristics are that two symmetrical reset springs (14) are installed between the opposite surface of the pressing plate (12) and the mounting plate (4), and the two ends of the reset spring (14) are connected with the side wall of the pressing plate (12) and the mounting plate (4) respectively. 5. The double-headed waterproof Pogo PIN mentioned in claim 2 is characterized by that the upper surface of the mounting plate (4) is fixedly connected with two limit plates (13) set symmetrically on the pressure plate (12), and the pressure plate (12) is connected with the side wall of the opposite face of the limit plate (13) by sliding. 6. According to claim 5, the double-head waterproof Pogo PIN is characterized in that the side wall thread of the limit plate (13) is connected with the finite bolt (11), and one end of the limit bolt (11) runs through the side wall of the limit plate (13) and is connected with the side wall thread of another limit plate (13).

Technical summary

The utility model discloses a

double-headed waterproof Pogo PIN, which relates to the technical field of electronic components. The utility model comprises a Pogo PIN shell, a side wall of the Pogo PIN shell is provided with a long needle tube, a long needle shaft is connected with a long needle shaft, and one end of the long needle shaft is extended out of the long needle tube and is connected with its sliding, the inner wall of the Pogo pin shell is fixedly connected with a riveting block inserted, and a long spring is arranged in the long needle tube. The other side wall of the Pogo pin shell is provided with a short needle tube, and a short needle shaft is connected with the sliding inside the short needle shaft. One end of the short needle shaft extends out the short needle tube and is connected with its sliding. The inner wall of the short needle tube is provided with a short spring, and the outer surface of the Pogo PIN shell is fixed and connected with a mounting plate through a clamping mechanism. The utility model solves the problems that most of the existing Pogo Pins are single-head design, which is difficult to effectively block the transmission of water, achieve absolute waterproof, and it is difficult to realize the design of bidirectional different elastic force requirements, and it is difficult to realize the leap-type conduction demand of long-distance demand. The problem of leapfrogging demand away from demand. The problem of leapfrogging demand away from demand.

Technical field

1. The utility model belongs to the technical field of electronic components, in particular to a double-headed waterproof Pogo PIN.

Background Technology:

2.Pogo Pin (Pogopin) is a kind of precision connector used in mobile phones and other electronic products, which is widely used in semiconductor equipment and plays the role of connecting. It has different appearance depending on the application, but overall Pogopin has a precision spring structure inside. Pogopin is a spring-type probe formed by riveting and prepressing three basic components of needle shaft, spring and needle tube through precision instruments. There is a precise spring structure inside the probe. The surface coating of Pogopin is generally gold-plated, which can better improve its anti-corrosion function, mechanical properties, electrical properties and so on. The needle tip has pointed needle, grasping needle, round head needle, knife type needle and so on. Pogopin is commonly used in the precision connection of mobile phone, communication, automotive, medical, aerospace and other electronic products, which can improve the corrosion resistance, stability and durability of these connectors. Because POgopIN is a very fine probe, the application of POgopin in precision connectors can reduce the weight and appearance of the volume of the connector, which can make the connector more fine and beautiful.

3. However, most of the existing Pogo pin, using all the needle hole type design, in use process, the liquid material can permeate into PCB side, and cause short-circuit destroyed machine consequences, most of the Pogo pin for single head design, effectively blocking water through hard, do they're absolutely water-proof, difficult to implement two-way elastic demand different design at the same time, It is difficult to realize the long-distance demand of leapfrog conduction demand, which brings great inconvenience.

4. In order to solve the above problems, the utility model proposes a double-head waterproof Pogo PIN.

Technical implementation elements:

5. The utility model aims to provide a two-headed watertight Pogo pins, solve the existing Pogo pin, mostly for the single head design, it is difficult to effectively block the water through, do they're absolutely water-proof, difficult to implement two-way elastic demand different design at the same time, it is difficult to realize long distance requirements leap-forward conduction demand, has brought great inconvenience.

6. In order to solve the above technical problems, the utility model is realized by the following technical solution:

7. The utility model is a double-head waterproof Pogo PIN, including a Pogo PIN shell, a side wall of the Pogo pin shell is provided with a long needle tube, the long needle tube is connected with a long needle shaft, one end of the long needle shaft is extended out of the long needle tube and is connected with its sliding, the inner wall of the Pogo pin shell is fixed connected with a riveting block, Described long needles have long spring is installed inside, described the ends of the long spring respectively with long needle shaft sidewall and riveting press block wall connection, described in the Pogo pin crust of another side wall runs short needles, described in the short needle sliding connection have short pin shaft, described the short needle shaft out at the end of the sliding connection with short needles, described the short needle tube inside wall set has a short spring, Described the ends of the short spring respectively with the wall and put pressure riveting pieces short pin shaft wall connection, as described in the outer surface of the Pogo pin shell by clamping mechanism installation plate is fixed connection, by setting the long needle, needle, needle axis and short axis etc., through the double sectional design, which can effectively block the water through the lifting device waterproof effect, At the same time, through the two-end split design, the design of bidirectional different elastic force requirements can be realized, and the leapfrog conduction demand of long-distance demand can be realized.

8. Further, the clamping mechanism including the mounting plate, groove, groove installation, top block, compression spring and card block, mounting plate wall runs and Pogo pin shell matching set slot, mounting plate surface runs through the slot, Pogo pin shell into mounting plate part wall open slot with installation, installation of sliding groove connection card block, The clamping block is inserted into the through slot and is connected with it by sliding

, installation groove side set a compression spring, compression spring respectively with card on both ends of block wall and the installation groove wall connection, groove sliding connection with the top piece, one end of the top piece out slot, by setting the mounting plate, groove, installation groove, top piece, compression spring and the block can be easy to remove the two-headed Pogo pin, and quick to install, It is difficult to remove and replace the existing device quickly.

jerry_shi2010

jerry_shi2010