2023-5-4 10:52:23

Why the pogo pin irreducible ?

So what exactly is the cause of the

pogo pin spring needle these problems? According to Cnomax pogopin factory more than 10 years of

pogopin connector industry experience to analyze, for the above points one by one:

1. There are many reasons for the pin. The first one is that the needle tube of the spring needle is crushed, which leads to the card not bouncing back. This problem may be caused by the manufacturer of pogopin or the manufacturer of electronic products and equipment in the process. The second kind has more than 90% probability caused by electronic product equipment manufacturers in the process, that is, when welding soft wire or PCB, the flux surplus is too much, through high temperature heating spread to the pipe mouth, resulting in the needle and needle stuck after cooling.

2. The cause of pogopin spring pin drop is relatively simple, either the manufacturer did not check out the mix, or the damage caused by bump in transit; Next is the damage of electronic products equipment manufacturers in the process, the needle of the spring needle is thin and fragile, if the force direction is not right or too large, it will cause the deformation of the pipe mouth, resulting in the needle falling. These problems are usually sporadic, as long as the cause is identified, are relatively easy to deal with.

3. The press is not smooth, dry, abnormal sound, and these problems will also occur when the pipe mouth is hurt and deformed by external force, but this is accidental and the number is very small. If the problem is batch specific and the quantity is very large, then there is a high probability that the manufacturer is to blame. The needle and needle tube of {pogopin spring needle} are turned out by precision turning machine (P4 machine and machine). If the machine is too poor or the aging accuracy of the machine is not enough, the surface of the needle and needle tube and the inner surface of the car will form a circle of similar threaded turning marks. These problems may "suddenly disappear" after electroplating, but they can occur suddenly with pressing friction, and they can occur in batches.

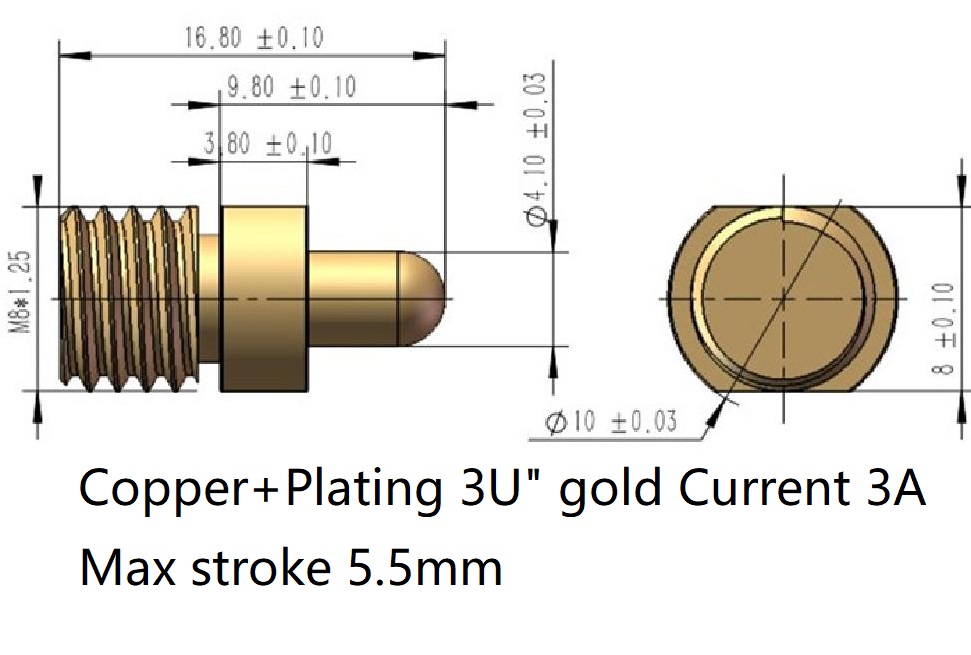

As for the internal spring fuse, burn involves the pogopin spring needle internal structure and large current problem, let's talk about the pogopin structure problem, pogopin more common internal structure are: anti-drilling, split inclined plane, double contact, inclined plane plus ball and so on. At present, reverse drilling and split plane structure are widely used. Reverse drilling is mostly used in small current (1A and below), and split plane is mostly used in large current (2-30A). Engineers usually take this into account when designing, but some structures do not do ground welding due to space or other reasons, so there is a great possibility that due to the excessive current at the moment of contact, the spring inside the needle will be fused or burned, resulting in the failure of the spring needle. There are usually two solutions to solve this problem. One is grounding to prevent high temperature melting caused by high instantaneous current, and the other is overload protection, which is to leave a margin on the basis of the actual current requirements. For example, the actual application demand is 2A, then increase the margin of 0.5-1A on the basis of this, and choose the pogopin application of 2.5-3A

Cnomax pogo pin factory, a number of structural utility model patents, more than 10 years of connector industry experience, design + production one-stop supply chain. Factory area of 12,000 square meters, dust-free purification workshop, 3000K/ month capacity. Provide free prenatal risk assessment, reduce customer risk coefficient, 3.0 mirror turning, hair process, press smoothly, no dry abnormal sound, no pin, no pin off, products adapt to a variety of harsh environment, industrial corrosion resistance grade, 11 QC strict inspection process, every detail is the standard, delivery on time

jerry_shi2010

jerry_shi2010